Vegetable protein

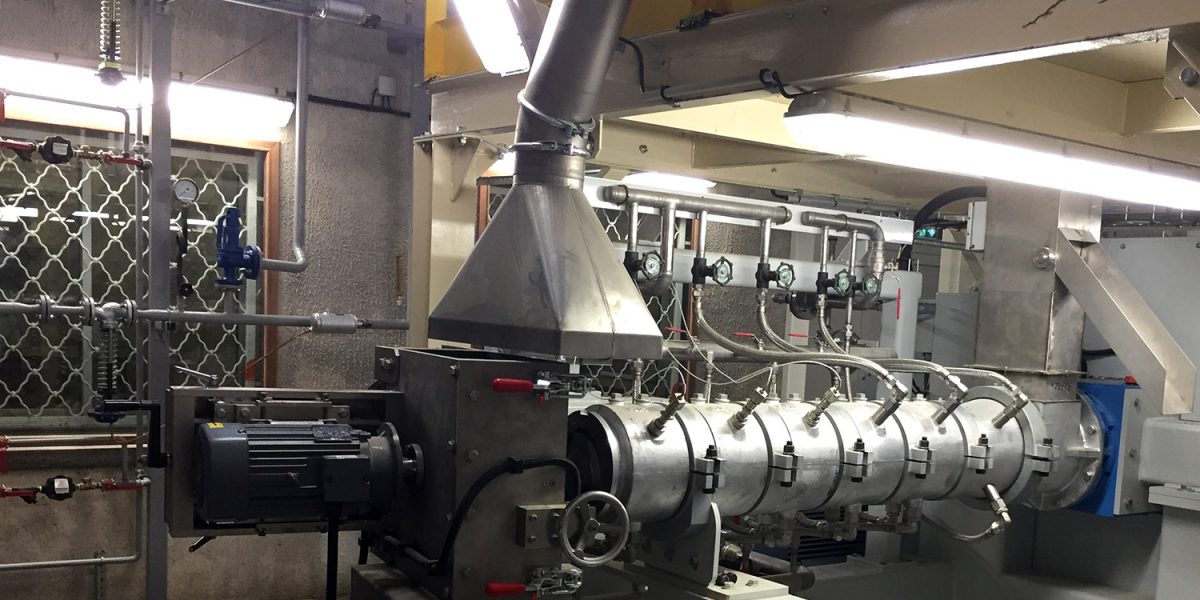

Vegetable protein extrusion: design your production lines

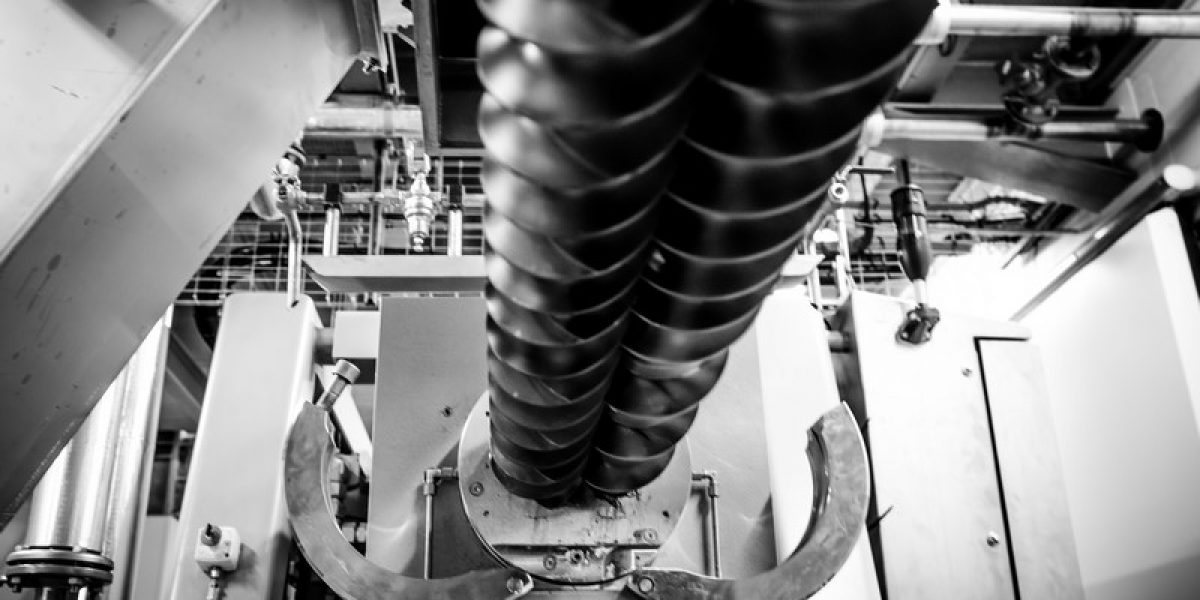

For a few years now, the food industry has been offering an alternative to animal proteins through the extrusion of vegetable proteins. Cooking-extrusion allows us to add new textures to the proteins of the bean, pea or soy.

There are two main product families:

-Textured Vegetable Protein (TVP) products that are dry and require rehydration before use.

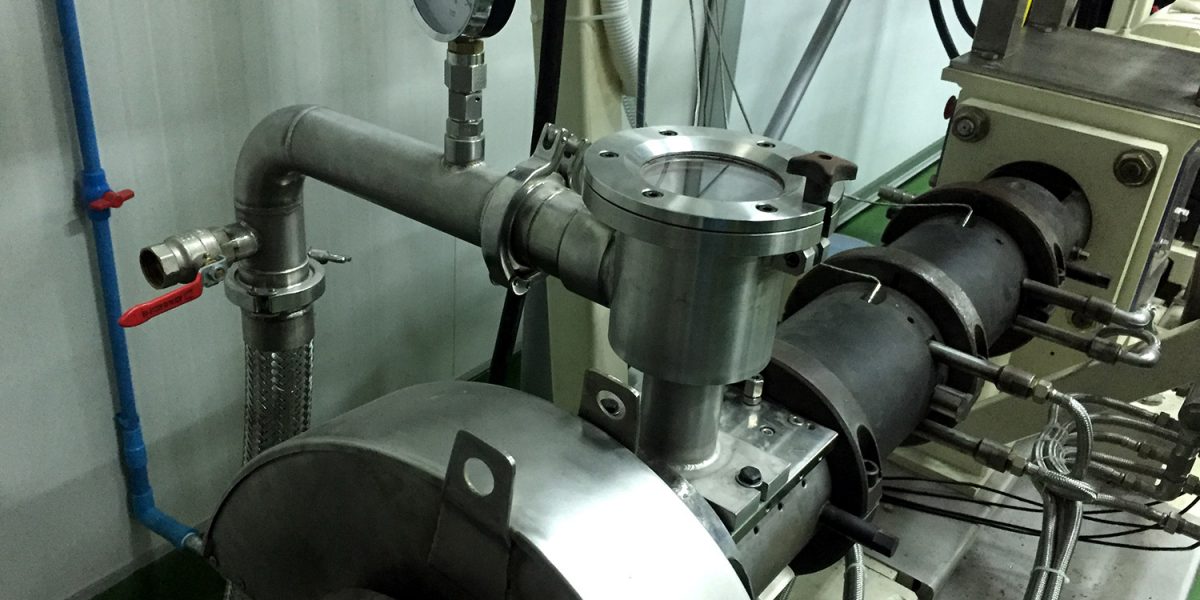

-High Moisture Meat Analogue (HMMA). These products contain a lot of water and must be treated as fresh products.

The equipment of your production line will be specific to the product family.

A custom design of your production lines for extruded proteins.

Depending on the type of products you want to manufacture, the technical choices will not be the same.

TGC EXTRUSION has a know-how and a field experience that will allow us to best meet your expectations to design, optimize, modify your cooking-extrusion lines to:

– Meat analogues to reproduce textures of chicken, pork, beef, fish,

– Chunk and other TVP

Our extrusion company advises you independently

We work closely with machine suppliers. But we are completely independent of the manufacturers. Our job is to target your needs precisely, so as to advise you by directing you to the machines most appropriate to your activity. We take up the challenges of your specific requests, if we do not find equipment that meets your need, we will custom design.

Extrusion specialists who anticipate your technical needs

Our business is not limited to the supply of equipment. TGC EXTRUSION has been supporting manufacturers for over 25 years. Our respective routes have given TGC EXTRUSION a very strong «field» orientation.

Our expertise will be used to:

– Support you in the R&D phase to design your products. In this regard, TGC EXTRUSION has obtained the Innovation Tax Credit Approval,

– Perform audits of your existing production units,

– Design custom parts or machines,

– Train operators.