Petfood

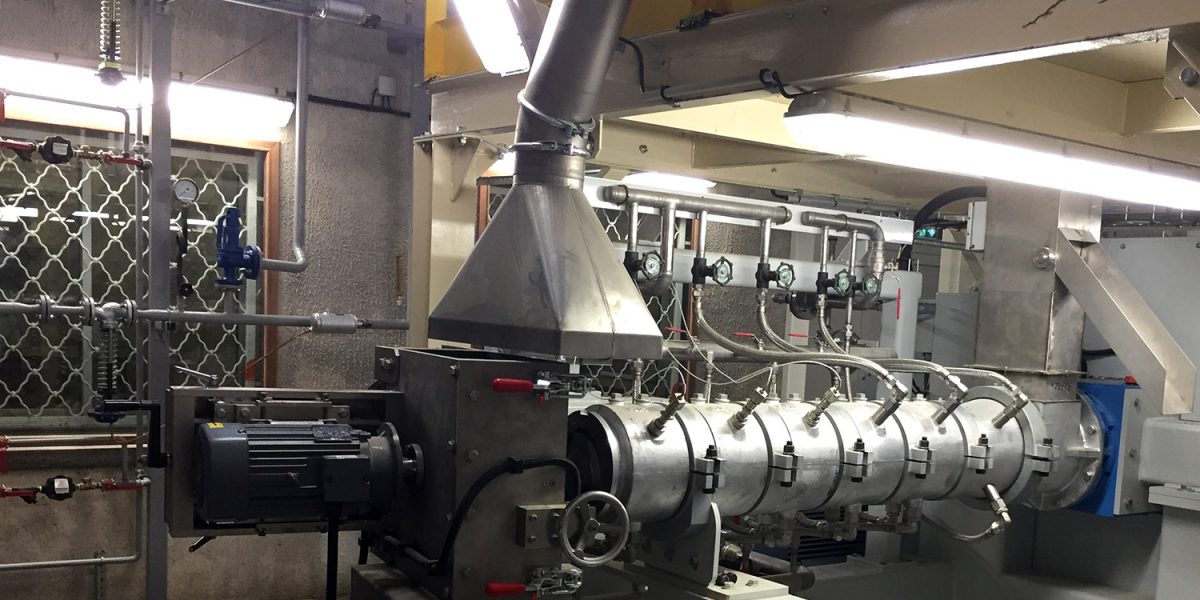

Design of Petfood lines (Dogs and Cats)

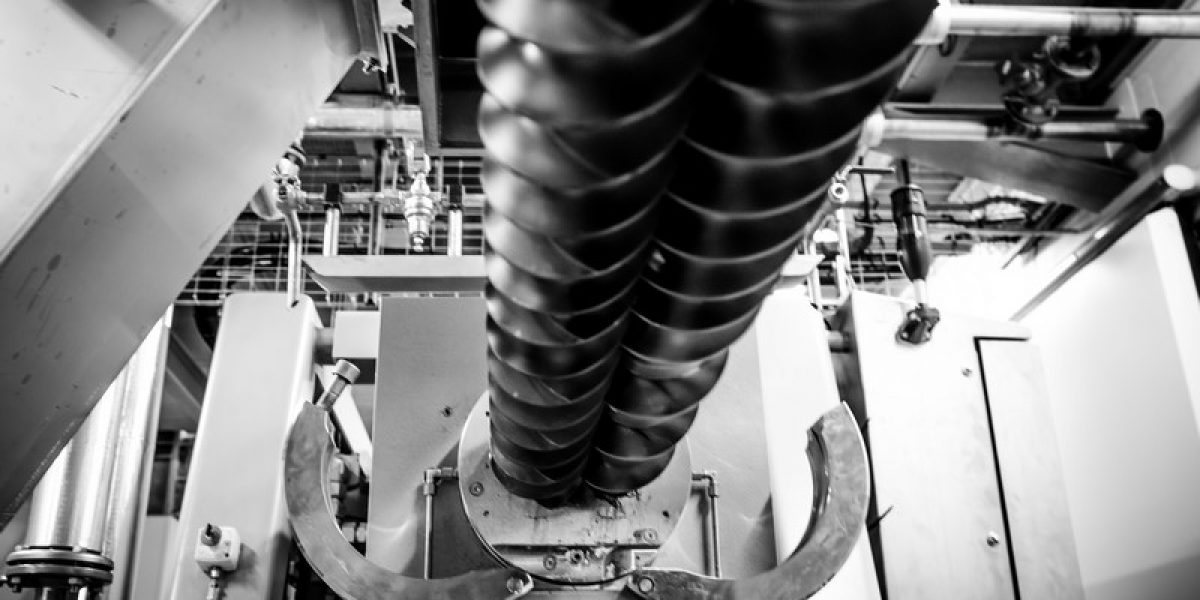

Petfood manufacturers were the first to use cooking-extrusion to produce dog and cat food.

This technique has allowed a great advance in terms of nutrition thanks to better cooking of ingredients (starches in particular).

At the same time, knowledge of the nutritional needs of these animals has progressed and technology has continued to evolve to meet these new needs.

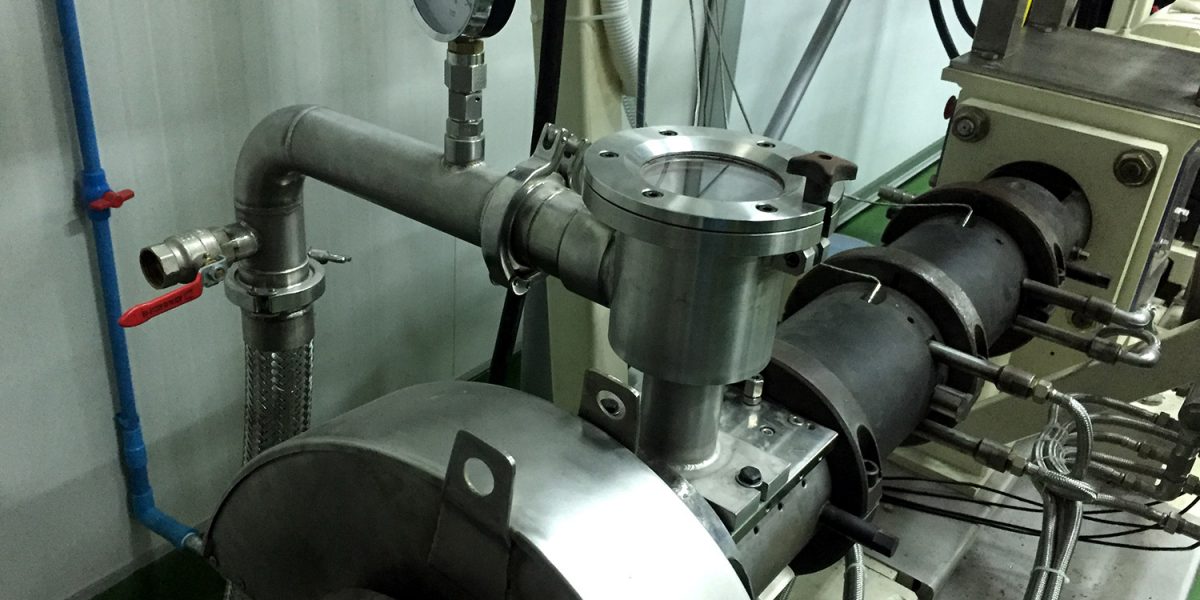

For example coating techniques, thanks to the use of vacuum allows a better incorporation of fats. A sequential coating can be made with several ingredients (a main fat at the heart of the kibble and others at the periphery). But this technique also promotes the addition of micro-ingredients (probiotics, palatant, etc.).

The density control at the extruder allows a perfect control of the filling of the bags.

Drying is a key step to ensure a good preservation of the product but not only, the choice of a suitable machine will ensure a precise target humidity; very important target to ensure crispiness depending on the type of animal fed. New energy solutions are coming to limit the financial impact.

The quality of flour milling is another crucial point for obtaining a better gelatinization of starch, to limit the presence of fines.

New products have appeared: coextruded for cats, treats for dogs and cats…

TGC EXTRUSION masters all these techniques and can bring you a turnkey project.

A custom design of your production lines for animal feed

Depending on the type of animal food you want to make, the technical choices will not be the same.

TGC EXTRUSION has a know-how and a field experience that will allow us to best meet your expectations to design, optimize, modify your cooking-extrusion lines to:

– New Pets (CAN),

– Dogs and cats,

– Various farm animals,

– Farmed or ornamental fish.

Extrusion specialists who anticipate your technical needs

Our business is not limited to the supply of equipment. TGC EXTRUSION has been supporting manufacturers for over 25 years. Our respective routes have given TGC EXTRUSION a very strong «field» orientation.

Our expertise will be used to:

- Support you in the R&D phase to design your products. In this regard, TGC EXTRUSION has obtained the Innovation Tax Credit Approval,

- Perform audits of your existing production units,

- Design custom parts or machines,

- Train operators.

Our extrusion company advises you independently

We work closely with machine suppliers. But we are completely independent of the manufacturers. Our job is to target your needs precisely, so as to advise you by directing you to the machines most appropriate to your activity. We take up the challenges of your specific requests, if we do not find equipment that meets your need, we will custom design.